What is SOP AI? Standard Operating Procedures (SOPs) have long been the backbone of efficient and safe operations in industries ranging from manufacturing to healthcare. They provide step-by-step instructions to ensure tasks are performed correctly, consistently, and in compliance with regulations. In recent years, a new element has entered the scene to enhance these traditional practices: Artificial Intelligence (AI). The fusion of SOP and AI – often termed “SOP AI” – is transforming how procedures are created, maintained, and improved. This article explores the concept of SOP AI by first examining what SOPs are and why they matter, then delving into the rise of AI in industry, and finally illustrating how AI-driven tools like the eTWi digital SOP system and the KaizenUp AI application are changing the game for standard work processes.

Table of Contents

ToggleUnderstanding Standard Operating Procedures (SOP)

What is an SOP?

A Standard Operating Procedure is a documented process that outlines how to perform a task or operation step by step. Essentially, an SOP is the “how-to” guide for any routine activity within an organization. By compiling instructions in a clear, sequential manner, SOPs aim to achieve efficiency, quality output, and uniformity of performance. They help reduce miscommunication and ensure that everyone follows the same method, thereby minimizing errors.

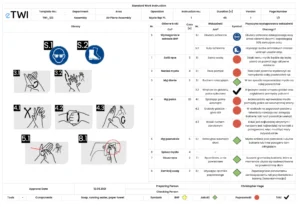

SOP AI by etwi

In a manufacturing setting, an SOP might describe how to safely operate a machine or assemble a product. Regardless of the domain, the core purpose of an SOP is to capture the best-known way to do a job and make sure that way is consistently applied.

Why SOPs Matter in Production Processes

SOPs play a critical role in production and operations. Here are several key reasons why having well-defined standard procedures is essential:

-

Consistency and Quality Control: SOPs ensure that each operator performs a task in the same approved manner, which leads to consistent results. This consistency is directly tied to product quality. When every worker follows the same steps and guidelines, there is less variation in output. Over time, well-implemented SOPs form the backbone of quality assurance by minimizing defects and rework.

-

Safety and Compliance: In industries with hazardous equipment or strict regulatory requirements, SOPs are vital for safety. They include detailed precautions and checkpoints that workers must follow to prevent accidents. By adhering to SOPs, companies also stay compliant with industry standards and legal regulations (such as OSHA guidelines or ISO standards). This not only protects employees but also shields the organization from liability and regulatory penalties.

-

Training and Knowledge Transfer: SOPs serve as training material for new employees and a reference for veteran staff. When onboarding new hires in a production environment, having documented procedures shortens the learning curve. Trainees can study the SOP document and even shadow an experienced worker following it. Clear SOPs help capture the expertise of seasoned employees, preserving institutional knowledge. This is especially important for preserving know-how when veteran workers retire or leave.

-

Efficiency and Productivity: SOPs often incorporate the most efficient way to do the job, saving time and reducing mistakes. They also streamline decision-making, since workers can refer to the SOP instead of asking managers how to proceed.

-

Basis for Continuous Improvement: In methodologies like Lean and Kaizen, you “standardize” before you “improve.” SOPs provide a baseline for how processes currently work. This makes it easier for teams to identify deviations or inefficiencies and then brainstorm improvements. When an improvement is found, the SOP can be updated to reflect the new best practice. In this way, SOPs are living documents that evolve through continuous improvement efforts.

From TWI to Today: A Brief History of SOPs

The concept of standardized work instructions has deep roots. During World War II, the Training Within Industry (TWI) program introduced a structured approach to quickly train new factory workers by breaking jobs into important steps, key points, and reasons for each key point. This method proved highly effective and became a foundation for modern SOP creation, emphasizing not just what to do, but how and why to do it.

In the following decades, these principles were adopted as part of quality systems and Lean manufacturing. SOPs evolved from paper binders to digital platforms, but the goal remains the same: capture the best way to perform a task and ensure everyone follows it.

The Emergence of AI in Industry 4.0

What is AI and How Is It Used in Manufacturing?

Artificial Intelligence (AI) refers to computer systems that perform tasks normally requiring human intelligence. In manufacturing, AI has rapidly become a game-changer, powering systems for predictive maintenance to reduce downtime, automating visual quality inspection on production lines, optimizing decision-making in supply chains, and even guiding smart robots on the shop floor. These successes illustrate the potential of AI to enhance many facets of production.

The Case for AI in Process Documentation

Given AI’s success in other areas of manufacturing, it was only a matter of time before it intersected with process documentation and training. Traditional SOP management is ripe for digital transformation. Some challenges with conventional SOPs include:

-

Time-consuming creation: Writing a new SOP from scratch can take hours or days of observing work, taking photos, and writing detailed descriptions.

-

Keeping documents up to date: When a process changes on the shop floor, updating the SOP (and getting everyone to use the new version) is often slow and sometimes neglected.

-

Human error and variability: One person’s description of a task might differ from another’s, leading to inconsistencies. Important details might be omitted unintentionally.

-

Accessibility: Paper manuals or even PDFs on a shared drive might not be easily accessible to workers at the exact moment they need guidance.

AI has the potential to address many of these issues. By leveraging AI for SOPs, companies aim to:

-

Speed up the documentation process – using tools that can help draft procedures quickly or even auto-generate steps from demonstrations.

-

Improve accuracy and detail – ensuring no critical step or key point is missed, as AI can flag inconsistencies or compare against best practices.

-

Facilitate easier updates – with AI tracking changes and suggesting edits when a process or regulation changes.

-

Make SOPs more accessible – for example, by integrating with digital devices, search functions, or even AI chatbots that can answer procedural questions on the fly.

This is where the concept of SOP AI emerges: using artificial intelligence to assist in creating, managing, and deploying Standard Operating Procedures.

How AI is Transforming SOP Creation and Management

AI-driven solutions are bringing a new level of intelligence and agility to the world of SOPs. Instead of static documents that sit on a shelf or in a folder, SOPs can become dynamic resources that are easier to create and continuously improve. Below are some of the key ways AI is enhancing SOP creation and management:

AI-Assisted SOP Authoring

One of the most direct impacts of AI is assistance in writing SOP content. Modern AI language models are capable of generating human-like text, which means an AI tool can help draft an SOP when given some initial information. For example:

-

The AI can suggest a standardized structure or template for the procedure based on industry best practices. If you’re writing a maintenance SOP, the AI might propose sections like “Tools Needed,” “Preparation,” “Step-by-Step Instructions,” and “Safety Checks,” ensuring you don’t forget key headings.

-

AI can generate detailed step-by-step instructions by analyzing your inputs. For example, if you describe a task briefly or provide an outline, the AI will flesh it out into a complete SOP draft.

The result is that drafting an SOP goes from a blank-page exercise to a guided process. Writers (often process engineers or experienced operators) become editors and verifiers of the AI’s suggestions, rather than having to write everything manually from scratch. This can save significant time and also ensure the SOP follows a logical, thorough format.

Turning Videos into SOPs

Perhaps one of the most groundbreaking developments in SOP AI is the ability to generate procedures from video footage. Consider this scenario: an expert worker performs a task while being filmed, and later an AI tool analyzes that video to produce the work instruction. Through computer vision and pattern recognition, an AI can analyze the footage and break it down into a sequence of discrete steps. For instance, KaizenUp will segment the video whenever the operator starts a new action. It then suggests what the operator is doing in each step, and highlights possible key points – critical details like a specific technique or precaution the operator took. The AI might not automatically know the “why” behind each key point, so it prompts the human expert to input the reason (for example, explaining that a certain bolt is tightened first to ensure proper alignment or a safety guard is used to prevent injury).

Often, the human supervisor or engineer will review the AI-generated steps and add any missing key points or reasons. But the heavy lifting – identifying the sequence of actions and drafting the initial text – is handled by AI. The end result is a draft SOP, complete with clear steps and even images grabbed from the video, compiled in a fraction of the time it would take to write it manually.

This approach improves accuracy and completeness. The SOP is literally based on how the job is done by a skilled operator, so it captures nuances that might be overlooked in a written description. It’s like having an automatic note-taker that watches an expert in action and writes the first draft of the training manual for you.

Intelligent SOP Management and Analytics

AI doesn’t stop at creation; it also transforms how we manage and improve SOPs after they are released. By integrating AI into a digital SOP system, organizations can glean valuable insights from how procedures are actually used on the shop floor. For instance, an AI-enabled platform might notice that one work instruction is rarely accessed (perhaps indicating it’s obsolete) while another is viewed very often (signaling a critical or troublesome process that might require further training or improvement). The AI can correlate error reports or quality issues to specific steps in an SOP, flagging if a certain step is frequently linked with mistakes so that supervisors can take a closer look. It can even cross-reference SOP usage with employee training records – automatically identifying who needs to be trained on a new or updated procedure – ensuring no one is left in the dark when standards change. In short, AI analytics help turn SOPs into proactive tools for continuous improvement, not just static instructions.

Case Study: Streamlining SOP Creation with eTWi and KaizenUp

To better understand SOP AI in action, let’s look at how a specific combination of tools – the eTWi digital SOP system and the KaizenUp AI application – works together to transform the SOP creation process.

eTWi – A Digital SOP Platform Aligned with TWI

eTWi is software that supports companies in creating, updating, and managing their SOPs and work instructions in a fully digital way. The name hints at an electronic take on TWI (Training Within Industry), meaning the system is built to incorporate TWI’s best practices for training and standardization. With eTWi, an organization can:

-

Create and edit SOPs easily: Authors can input step-by-step instructions using a predefined template (customizable to the organization’s needs). They can add photos or diagrams directly in the instructions, making them visual and clear.

-

Manage revisions and approvals: The system keeps track of versions and changes. Whenever an SOP is edited, it can go through an approval workflow to ensure the updates are reviewed. This guarantees that only the latest, approved version is available to the workforce.

-

Distribute SOPs digitally: Instead of printed manuals, operators access SOPs on screens. eTWi allows workers to pull up instructions on a computer or mobile device; each SOP can be accessed via a QR code posted at the workstation, so the correct procedure is always just a scan away.

-

Integrate with training records: eTWi isn’t just a document repository – it ties into a training matrix. This means you can link each SOP to the employees who are trained to perform it. If an SOP is updated, the system can flag which employees need to be retrained or at least notified of the change.

-

Support continuous improvement: The platform treats SOPs as living documents. Users (like operators or team leaders) can leave comments or feedback on an SOP if they see an opportunity for improvement or clarification. This makes it easier to capture improvement ideas and implement them by updating the standard.

In essence, eTWi provides the digital infrastructure to ensure that standard work is easily accessible, up-to-date, and integrated with employee development.

KaizenUp – AI-Powered Assistant for SOP Creation

KaizenUp is an AI-driven application designed to support continuous improvement (Kaizen) and standardization efforts. One of its standout features in the context of SOP AI is the ability to analyze videos of a process and generate a draft SOP content. Here’s how it works in practice:

A team leader or engineer records a video of an operator performing a task, say assembling a component. They then upload this video into the KaizenUp app. The AI in KaizenUp processes the video to understand what’s happening:

-

Step identification: The AI breaks the video timeline into distinct steps whenever it detects the operator moving to a new part of the task. For example, “Step 1: Pick up Part A,” “Step 2: Install Part A onto Part B,” “Step 3: Secure with screws,” and so on.

-

Key point suggestion: KaizenUp tries to notice if the operator does something special or important in each step. For instance, if the operator aligns Part A in a certain way before securing it, the AI flags that as a key point (e.g., ensure Part A is flush with the base before tightening). If the operator checks a gauge or uses a specific tool, those might be key points too.

-

Reason prompting: For each key point, the AI might not inherently know why it’s important – that’s expert knowledge. So the app will prompt the human user to input the reason. In our example, the supervisor might add, “if Part A is not flush, the assembly will be misaligned, leading to defects.” Now the draft SOP will include not just what to do, but why it must be done that way (true to TWI principles).

KaizenUp essentially serves as a smart assistant that extracts the know-how from the video. It provides a structured draft: a list of steps with suggested key points and empty fields for reasons to be filled in. The supervisor reviews this, fills in any blanks (adding a missing step or correcting a description), and finalizes the content.

From AI Draft to Digital SOP

Once the AI (KaizenUp) has helped generate a solid draft of the procedure, it’s time to formalize it in the company’s standard format and roll it out for use. This is where eTWi comes back into play:

-

Review and Import: The supervisor takes the finalized job breakdown from KaizenUp (steps, key points, reasons) and imports or copies it into the eTWi system’s SOP template. Because eTWi supports the same structured format, this is straightforward.

-

Finalize in eTWi: Within eTWi, the supervisor can add any additional context or sections needed (such as listing required tools, PPE, or initial setup instructions). They can also attach the images captured from the video to the corresponding steps, so operators will see a picture of each step as they read the instructions.

-

Approval workflow: The new SOP is then submitted for approval in eTWi. Perhaps a quality manager or a senior engineer gets a notification, reviews the SOP content, and approves it. eTWi records this and time-stamps the new “Revision 1” of the SOP.

-

Publication and access: As soon as it’s approved, that SOP becomes instantly available to all who need it. Operators at the workstation can scan the SOP’s QR code or open the app to find the instruction by name. They will now see the updated instructions with all the new details. There’s no need to print or distribute anything physically – everyone sees the same single source of truth.

-

Training integration: eTWi will also log this SOP in the training matrix. If it’s a brand new SOP for a task, the system can list all operators in that area as “untrained” on this SOP until they’ve been briefed or formally trained. If it’s a revision to an existing SOP, eTWi can mark who needs to be notified or retrained due to the changes. This closes the loop so that creating the SOP isn’t just documentation, but immediately tied into ensuring workers are up to speed.

This seamless flow from video → AI draft → digital SOP system can dramatically shorten the time it takes to go from identifying a best practice to having it standardized and in use on the shop floor.

Results: Faster, Better, and Continuous Improvement

Using the combined power of KaizenUp and eTWi, the company in this case study significantly reduced the time needed to document procedures. A process that once took an expert nearly a full day to write up was captured and published in just a couple of hours with AI assistance. The resulting SOP was also richer in detail – it included photos and key insights from the veteran operator that may have been missed in a traditional write-up. Moreover, because the SOP was instantly accessible through the digital system, operators began following the new standard immediately, and training records were automatically updated. What used to be a tedious paperwork exercise was transformed into a swift, interactive routine, allowing engineers and supervisors to spend more time on improving processes rather than just documenting them.

Benefits of Using AI for SOP Creation

Bringing AI into the SOP lifecycle yields numerous advantages for businesses. Below is a summary of the key benefits:

-

Speed and Efficiency: AI dramatically reduces the time and effort required to create and update SOPs. New processes get documented faster, and employees have the guidance they need without delay.

-

Higher Quality Documentation: AI-assisted tools ensure SOP content is thorough and consistent. They help eliminate errors or omissions and maintain a uniform format and tone. The result is clear instructions that are less prone to misinterpretation, leading to fewer mistakes on the shop floor.

-

Shorter Training Times: Clear, AI-generated SOPs (often enhanced with images or video snippets) make it easier for new employees to learn their tasks. When instructions are easy to understand and always available, workers become proficient faster, reducing the overall training period.

-

Enhanced Compliance and Safety: AI can cross-check procedures against safety regulations and best practices. It might flag if a critical safety step is missing or suggest additional checks. This ensures that SOPs embed compliance from the start, helping prevent accidents and avoiding regulatory issues.

-

Living Documents & Continuous Improvement: Hosting SOPs in a digital platform (such as eTWi) augmented by AI means procedures are easy to update and improve continuously. The AI might analyze usage data or process results and notify you if a certain step needs revision. In this way, SOPs remain “living documents” that evolve as better methods are discovered, rather than becoming stale paperwork.

-

Empowered Workforce: By automating the drudgery of writing and managing SOPs, AI frees up supervisors, engineers, and operators to focus on more value-added activities like problem-solving, innovation, and coaching. With AI integration, updating an SOP with a great idea from the shop floor is fast, demonstrating to employees that their continuous improvement suggestions are truly welcomed and implemented.

Embracing the Future: SOP AI in Your Organization

In summary, SOP AI represents a powerful evolution of operational excellence. It merges the time-tested value of standard procedures with the cutting-edge capabilities of artificial intelligence. Companies that have begun to adopt this approach – using tools like eTWi and KaizenUp – are already seeing faster documentation, more consistent processes, and a more engaged workforce.

The future of SOPs is clearly leaning towards intelligence and adaptability. Even with the tools available today, embracing SOP AI gives organizations a competitive edge. It ensures that every process is documented and optimized, that every employee has the latest knowledge at their fingertips, and that improvement is a continuous cycle built into the workflow.

By leveraging AI in your SOP creation and management, you are not just writing procedures – you are cultivating a resilient, learning organization. The path forward is one where standard operating procedures are never static, but are intelligent assets that drive quality, safety, and efficiency to new heights. In this new era, the standard procedure is one that keeps getting better, and AI is the catalyst making it possible.